In chemistry, a catalyst is a substance that causes or accelerates a chemical reaction without itself being affected. Catalysts participate in the reactions, but are neither reactants nor products of the reaction they catalyze. In the human body, enzymes are naturally occurring catalysts responsible for many essential biochemical reactions

In the catalytic converter, there are two different types of catalyst at work, a reduction catalyst and an oxidation catalyst. Both types consist of a ceramic structure coated with a metal catalyst, usually platinum, rhodium and/or palladium. The idea is to create a structure that exposes the maximum surface area of catalyst to the exhaust stream, while also minimizing the amount of catalyst required, as the materials are extremely expensive. Some of the newest converters have even started to use gold mixed with the more traditional catalysts. Gold is cheaper than the other materials and could increase oxidation, the chemical reaction that reduces pollutants, by up to 40 percent [source: Kanellos].

Most modern cars are equipped with three-way catalytic converters. This refers to the three regulated emissions it helps to reduce.

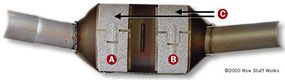

The reduction catalyst is the first stage of the catalytic converter. It uses platinum and rhodium to help reduce the NOx emissions. When an NO or NO2 molecule contacts the catalyst, the catalyst rips the nitrogen atom out of the molecule and holds on to it, freeing the oxygen in the form of O2. The nitrogen atoms bond with other nitrogen atoms that are also stuck to the catalyst, forming N2. For example:

2NO => N2 + O2 or 2NO2 => N2 + 2O2

2NO => N2 + O2 or 2NO2 => N2 + 2O2

The oxidation catalyst is the second stage of the catalytic converter. It reduces the unburned hydrocarbons and carbon monoxide by burning (oxidizing) them over a platinum and palladium catalyst. This catalyst aids the reaction of the CO and hydrocarbons with the remaining oxygen in the exhaust gas. For example:

2CO + O2 => 2CO2

There are two main types of structures used in catalytic converters — honeycomb and ceramic beads. Most cars today use a honeycomb structure.

In the next section, we’ll look at the third stage of the conversion process and how you can get the most from your catalytic converter.

Controlling Pollution and Improving Performance

The third stage of conversion is a control system that monitors the exhaust stream, and uses this information to control the fuel injection system. There is an oxygen sensor mounted upstream of the catalytic converter, meaning it is closer to the engine than the converter. This sensor tells the engine computer how much oxygen is in the exhaust. The engine computer can increase or decrease the amount of oxygen in the exhaust by adjusting the air-to-fuel ratio. This control scheme allows the engine computer to make sure that the engine is running at close to the stoichiometric point, and also to make sure that there is enough oxygen in the exhaust to allow the oxidization catalyst to burn the unburned hydrocarbons and CO.

The catalytic converter does a great job at reducing the pollution, but it can still be improved substantially. One of its biggest shortcomings is that it only works at a fairly high temperature. When you start your car cold, the catalytic converter does almost nothing to reduce the pollution in your exhaust.

One simple solution to this problem is to move the catalytic converter closer to the engine. This means that hotter exhaust gases reach the converter and it heats up faster, but this may also reduce the life of the converter by exposing it to extremely high temperatures. Most carmakers position the converter under the front passenger seat, far enough from the engine to keep the temperature down to levels that will not harm it.

Preheating the catalytic converter is a good way to reduce emissions. The easiest way to preheat the converter is to use electric resistance heaters. Unfortunately, the 12-volt electrical systems on most cars don’t provide enough energy or power to heat the catalytic converter fast enough. Most people would not wait several minutes for the catalytic converter to heat up before starting their car. Hybrid cars that have big, high-voltage battery packs can provide enough power to heat up the catalytic converter very quickly.

Catalytic converters in diesel engines do not work as well in reducing NOx. One reason is that diesel engines run cooler than standard engines, and the converters work better as they heat up. Some of the leading environmental auto experts have come up with a new system that helps to combat this. They inject a urea solution in the exhaust pipe, before it gets to the converter, to evaporate and mix with the exhaust and create a chemical reaction that will reduce NOx. Urea, also known as carbamide, is an organic compound made of carbon, nitrogen, oxygen and hydrogen. It’s found in the urine of mammals and amphibians. Urea reacts with NOx to produce nitrogen and water vapor, disposing more than 90 percent of the nitrogen oxides in exhaust gases